Scientific drilling - telescope into the Earth's interior

With the exception of tunnels and mines, the Earth's interior is largely inaccessible to us humans. Through drilling, direct access to the geological subsurface is established. The aim of scientific drilling is to gain a comprehensive understanding of the processes in the subsurface. Drilling is the only method that provides both data and samples from the depths and is applied in various different scientific disciplines.

With a borehole, a hole a few centimeters in diameter is drilled hundreds of meters or even several kilometers deep into the rocks of the Earth's crust. This creates access to the depths and allows cores to be retrieved and studied. What type of rocks and which fluids and microbes are encountered and how do they interact with each other under real underground pressure and temperature conditions? What forces are exerted on the underground through movement of the continental plates, the rise of magma, the erosion of rocks and glaciers at the surface, the seepage of water? All these questions can often only be inadequately recreated in the laboratory or modelled on the computer. Drillings are therefore necessary in many cases for a better understanding of the processes at depth.

Scientific drilling as a method for exploring the subsurface

Scientific drilling serves to:

- Explore the basic processes for the sustainable extraction of geo-resources such as geothermal energy, but also ores, or the safe storage of carbon dioxide in the underground;

- Research into natural hazards such as earthquakes, volcanic eruptions, landslides, in order to understand basic physical and chemical processes and to be able to recognize and warn of hazards at an early stage;

- Gain knowledge about how the diverse environmental and climatic changes in the Earth's history were triggered or reversed and which drivers there are in this complex system of air, water, continents and living beings, in order to be able to make predictions for the future;

- Research into the dynamic forces and processes in the Earth's interior, which are the foundations for all internal processes of mountain building, earthquakes, volcanism and thus crucial for the habitat and resources of humans.

![[Translate to English:] Übersicht geowissenschaftliche Themen](/fileadmin/_processed_/7/2/csm_Grafik-Uebersicht-harms_dd43d1026d.jpeg)

Research questions for which the scientific drilling method is used:

- Geodynamics — How did the Earth's crust, mantle and plate tectonics develop in the 4.5 billion years of Earth's history? How did life develop and what influence does it have on the Earth system, the water, the atmosphere?

- Geo-resources — How can energy, especially geothermal energy, and raw materials be obtained in a sustainable and environmentally friendly way? How can energy be stored underground, for example in the form of hydrogen?

- Geohazards — What forces cause earthquakes or volcanic eruptions and how can we reliably warn of dangers as early as possible to minimize risks?

- Past environmental and climate changes — What factors have driven drastic changes in the long geological past and what role does the deep biosphere play in this?

How to drill?

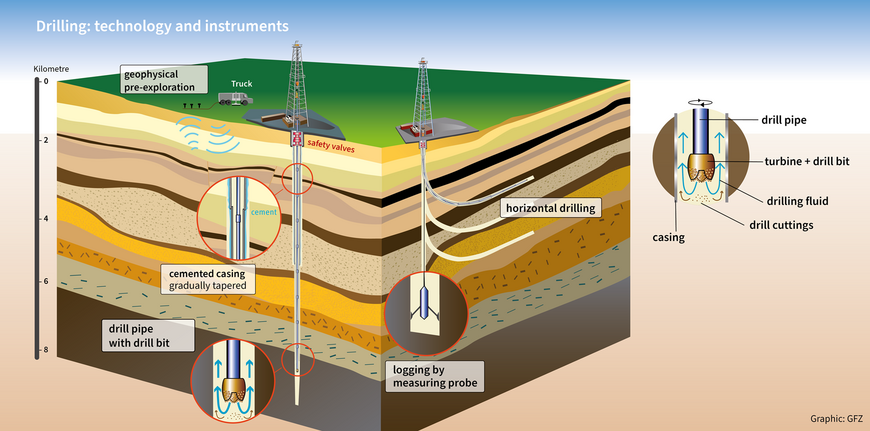

For drilling of deep boreholes, a hollow drill pipe is screwed to a drill bit within a special crane (drill rig) and lowered into the ground. Drilling fluid is pumped through the drill pipe and the drill bit rotates with the aid of a turbine. The drilling fluid also cools the bit and transports the so-called cuttings out of the borehole. This method can be used to drill several kilometres deep into rock. Depending on the stability of the borehole wall and on the occurrence of groundwater and deep water in the rock, a borehole is cased in sections and the casing is cemented into place, resulting in a borehole that is narrower in lower sections of the hole.

To obtain intact samples, drilling methods are used in which the drill bit is replaced by a hollow drill bit. This allows a column of rock to glide into the drill pipe during drilling. The drill core can be brought to the surface after a few meters of drilling. This can be done by removing the entire drill string or by pulling a special inner core tube with a rope.

Borehole measurements and instruments

After each drilling section, the drilled-through rocks are measured with geophysical probes. These instruments are lowered into the borehole on special cables. The hole is then scanned with sensors that register a continuous profile of physical, chemical and mechanical properties. For long-term monitoring, instruments can be anchored within the borehole over longer periods, for example to monitor deformations and any earthquake hazard. Underground measurements are much more sensitive than on-surface monitoring which is prone to many natural or man-made interference signals. Nowadays, fibre optic cables can even be used to measure temperature or stress throughout the entire borehole, which is essential for earthquake research or geothermal use.

How deep is drilling?

Scientific boreholes can be a few tens, hundreds or even thousands of meters deep, depending on the research question. For environmental and climate research, boreholes down to 500 m deep are often sufficient if locations with required samples at shallow depths have been pinpointed in advance using geophysical deep sounding. However, in the Songliao sedimentary basin in northeast China, drilling was done to a depth of 7000 m to reach the early Cretaceous deposits. In the KTB project in Windischeschenbach in Bavaria, it was possible to drill 9100 m deep in the early 1990s to reach areas where temperatures of over 260° Celsius change the rock properties. With this depth, the technical limit of deep drilling at that time was reached.

International Continental Scientific Drilling Program

The International Continental Scientific Drilling Program (ICDP) supports international research teams financially and with technical and scientific support such as equipment and know-how. Groundbreaking new discoveries have been made while drilling with ICDP backing. For the first time, a well was able to penetrate and sample the San Andreas Fault (to study deformation and earthquakes), a magma chamber was safely drilled in Iceland (to develop new energy sources), the North Anatolian Fault was instrumented with wells around the Sea of Marmara (to enable better predictions for future earthquakes), the Chicxulub crater in Mexico was drilled (to study the meteorite impact that led to the extinction of the dinosaurs), lake sediments in all climate zones (Baikal, Titicaca, Malawi, Bosumtwi, Potrok Aike, Elgygytgyn, Dead Sea, Ohrid, Towuti) were drilled (to understand the last million years of climate changes on Earth). In total, 64 drilling projects have been funded by ICDP over 27 years.

Training courses for young talents

Not only the research aspects of ICDP are significant, but also the opportunity for students to learn about technology and science at boreholes and to further their education. To this end, ICDP regularly organizes further education courses. In addition, many ICDP boreholes offer extensive opportunities for visits and information.

To ICDP-Program

Scientific drilling is an important method in the geosciences. It is used to obtain data and samples from the geological subsurface to investigate scientific questions.

Scientific drilling is necessary to observe and measure processes such as the formation of earthquakes or the sustainable use of resources under natural conditions. Drillings are also used to obtain rock samples that can be used to reconstruct past environmental and climatic conditions.

The deepest borehole to date reaches a depth of 12,266 m and was drilled on the Kola Peninsula near Zapolyarni in north-west Russia. It was drilled from 1970 to 1989 as a scientific borehole (Teufe = depth in miner's jargon) to explore the structure of the Earth's interior and, for example, ore deposits down to great depths. Today, there are some "longer" wells drilled to produce natural gas under the sea from land, but these commercial wells are horizontally deviated at 1000 or 2000 m depth, and thus their actual vertical depth is only about 2000 to 3000 m.

Thanks to 150 years of experience in drilling technology, drilling on land is very safe today. In Germany and Europe, mining authorities approve and monitor deep drilling in great detail so that environmental hazards can be largely ruled out. Moreover, research drilling is only undertaken where very extensive preliminary investigations have ruled out risks such as pressurized gas.

Basically, a so-called fluid exchange is to be prevented. This is understood as a possible mixing of salt water and groundwater or the rise and escape of natural gas or crude oil. To prevent this, plastic or metal pipes are cemented into the borehole wall in sections and a system of sealing cocks is attached to the head of the borehole, thus sealing the borehole. The mud circulating within the borehole is monitored for signs of pressure increase or gas rise. If necessary, the density of the drilling fluid is adjusted with weighting agents to prevent breakout. Boreholes must be sealed with cement from bottom to top after use to guarantee for the permanent closure of the hole.

Risks must also be minimized when using boreholes. When oil or hot water is extracted, or when water or gas is injected, the underground pressure conditions in the cracks and pore space of the surrounding rock change. This can lead to crack widening or even fracturing in the rock, which manifests itself as microseismicity or earthquakes. Fortunately, today it is possible to detect even the smallest precursors of magnitude -2, called microquakes, with particularly sensitive seismometers and to throttle back or stop the injection before larger quakes occur. Slow pressure equalization then leads to the release of stresses without quakes noticeable at the surface.

Such test procedures, called "adaptive stimulation", are carried out, for example, in research boreholes to explore the creation of artificial heat exchangers for geothermal use. Rocks at greater depths are hotter (the temperature rises by 30° per kilometer deep), and they are also denser. So you cannot simply inject cold water into one borehole and pump hot water into an adjacent borehole without having created an artificially high permeability. To this end, the GFZ is conducting the GEOREAL experiment in its KTB deep laboratory, for example. In geothermal projects, we speak of hydraulic stimulation. In this process, water — sometimes with additives (some sand, others chemical thickeners) — is injected into boreholes at high pressure to create fractures in the subsurface for better flow and heat exchange. In geothermal energy, artificial additives are usually not used during injection.

Research wells are only occasionally drilled for specific scientific questions. For the exploration and use of geothermal energy, however, drilling has been increasing in southern Germany for some years, for example in the Munich area and in the Upper Rhine Valley Graben. There, the potential to hit high temperatures of over 100°C already at a depth of 3000 to 5000 m is high. The rocks have good permeability, which means that these reservoirs serve as good, natural heat exchangers. In the north and east of Germany, permeable rocks are also often found between a depth of 1000 and 2000 m, from which 40 to 70 °C hot water can be extracted to supply modern low-temperature heating systems, for example. In the winter of 2022/2023 the company EWP in Potsdam drilled a borehole for geothermal use. This borehole is over 2000 m deep and was drilled on the Heinrich-Mann-Allee in Potsdam, very close to the GFZ.

Existing boreholes are also needed for experiments in the long term. The GFZ is using the 4 and 9.1 km deep boreholes of Germany's Continental Deep Drilling Programme as a deep laboratory to test the possibility of creating artificial heat exchangers by injecting water at a depth of 4 km. There are similar projects in the North German Basin in Brandenburg near Gross-Schoenebeck, where geothermal energy is being researched.

Links

Information on scientific drilling

- GFZ Section 4.2 Overview: Geomechanics and Scientific Drilling

- Seismic monitoring: Plate Boundary Observatory Turkey

- ICDP International Continental Scientific Drilling Program: Webpage

- Network to establish 3D underground seismics 3D-US Lab

- GFZ-Journal (2014) System Erde, Focus: Scientific Drilling

- GEO-Zentrum an der KTB (in german)

Press releases

![[Translate to English:] Blick ins Bohrloch von oben](/fileadmin/_processed_/c/0/csm_AdobeStock_452333154-header_85b251dbe3.jpeg)