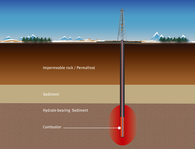

In order to extract methane from natural gas hydrates conventional production methods of the oil and gas industry are further developed. The aim is to decompose the hydrate already in the sediment (in situ) so that only methane is produced through a conventional well but not water or the surrounding sediment.

At the GFZ German Research Centre for Geosciences, the gas hydrate research group, headed by Judith Schicks, is developing a method which decomposes gas hydrates by the supply of heat. The heat is generated by a flameless catalytic combustion of methane in a so-called counter-current heat exchange reactor ‒ the Schicks Combustor. In future, the Schicks Combustor will be placed in the borehole within the hydrate-bearing sediments in such way that the hot reaction zone is situated in the area of the hydrate layer. First results from field tests without hydrate show that the Schicks Combustor efficiently and safely produces heat in the subsurface. The Schicks Combustor was designed as a lab reactor and a borehole tool, has been successfully tested and is available for application tests.

The Schicks Combustor generates heat via a flameless catalytic oxidation of methane at a noble metal catalyst. Instead of pure oxygen, air is used for the oxidation of methane. This has the advantage that the temperature in the catalyst bed does not rise so much since the nitrogen in the air has a cooling function. In order to ensure a safe supply of methane and air into the catalyst bed the reactants are fed separately through a tube-in-tube arrangement into the mixing chamber. From there, they arrive in small quantities on the catalyst bed, where methane and the oxygen in the air are converted into carbon dioxide and water. Nitrogen is not converted and flows back together with the exhaust fumes. The hot product gases release their heat via an aluminium foam to the outer wall of the reactor and then to the environment. Simultaneously, the incoming gases are preheated. The reaction runs stable and autonomous between 400°C and 550°C. The water produced during the reaction is collected in a water trap and pumped out. This prevents the catalyst material from being damped by water vapour condensation and limited in its function.

Fig.: Principle of operation of the Schicks Combustor

The dissociation of methane is an endothermic process, i.e. a reaction where heat has to be supplied to. This is about 52 kJ/mol. The complete oxidation of methane on the catalyst is an exothermic reaction which releases a large amount of heat to the atmosphere. The total oxidation of methane releases the following amount of heat:

Fig.: Complete oxidation of methane

The Schicks Combustor as lab reactor

The lab prototype of the Schicks Combustor was tested in a reservoir simulator in order to investigate the heat transfer into gas hydrate bearing sediments. Therefore methane hydrate was generated in the LArge Reservoir Simulator (LARS) having a volume of 425 litres which was also developed at GFZ. During a test with 80% hydrate saturation the reservoir simulator warmed up within 12 hours so much after the ignition of the catalyst that the temperature of the complete sample was above the dissociation temperature of methane. The methane hydrate generated before dissociated completely and methane gas could be produced. During this test, only 15% of the produced methane was consumed to generate the energy needed for the thermal dissociation of the hydrates during the production test.

Fig.:LArge Reservoir Simulator LARS with lab reactor; Photograph of the lab reactor

The Schicks Combustor as borehole tool

The experience with the laboratory reactor served as basis for the design of a borehole tool which is suitable for the application in natural gas hydrate deposits. The borehole tool has a total length of 5200 mm, an outer diameter of 90 mm and weighs ca. 100 kg. For heat generation, methane and air are transported separately from the surface into the borehole tool. The carbon dioxide produced during catalytic combustion is returned separately to the earth's surface. The borehole tool is equipped with a specially developed pump that can transport the resulting reaction water in the borehole to the outside against a pressure gradient of up to 35 MPa. In its current form, the borehole tool has a heating capacity of 11 kW.

The borehole tool was subjected to a pressure and functional test in the depth laboratory of the GFZ at the Continental Deep drill hole in Windischeschenbach, in the Upper Palatinate area. The compressive strength of the tool was successfully tested to a depth of 2000 m (20 MPa). During the functional test, which was carried out at a depth of 630 m, the catalyst was ignited and methane was converted.

Fig.: Experimental site at the Continental Deep drill hole in Windischeschenbach, Oberpfalz (GFZ/KTB archive); photo of the borehole tool

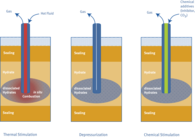

For the extraction of gas from gas hydrates, the equilibrium between hydrate and environment must be disturbed so that the stability conditions can no longer be achieved. Three different approaches are pursued for this purpose: depressurization, thermal stimulation and chemical stimulation.

The development of the Schicks Combustor is based on conventional methods of thermal oil extraction. One method of tertiary oil recovery (enhanced oil recovery) is in situ combustion, which has already been used for several years to improve the oil yield. The principle of generating the heat locally in the hydrate-bearing sediment is also interesting for the decomposition of gas hydrates with regard to gas production. In contrast to in situ combustion or other methods used in thermal oil extraction, there is no direct contact between the reaction zone or the reaction products and the reservoir.

Fig.: Basic methods of extracting gas from natural hydrate reservoirs

The Schicks Combustor – From laboratory to field to application

Since 2001, GFZ scientists have been working on gas hydrates. One focus is on fundamental research, which involves not only natural samples but also hydrates of defined composition being synthesized and analysed in the laboratory. The aim of these experiments is to determine the thermodynamic, kinetic and physical properties of these gas hydrate samples using electron microscopy, Raman spectrometry, calorimetry and X-ray diffraction. The results of these experiments form the basis for a better prediction of the behaviour of natural gas hydrates in the case of changes in their environment, e.g. global warming. However, they are also important for applied research with regard to the production of hydrate-bound methane.

The Schicks Combustor is a project that has accompanied the gas hydrate research group for more than 10 years. During this time, two prototypes of a laboratory reactor were built, which proved the efficiency and safety of the process. In order to test the function of the laboratory reactor, a reservoir simulator, which is unique at that time, was built with a volume of 425 L and in which gas hydrates can be generated at pressures of up to 25 MP. In the next step, the laboratory reactor was further developed into a borehole tool that can be used in gas hydrate-bearing sediments. The compressive strength and the function of the borehole tool were demonstrated in tests at depths of up to 2000 m.

In the upcoming years, natural gas will play an increasingly important role in the energy supply because, compared to other fossil fuels, it burns comparatively clean. For this reason, the production of gas from gas hydrates is also regarded as a transformation technology on the way from fossil to renewable energies. One way of decomposing gas hydrates thermally in order to be able to produce the gas subsequently is the Schicks Combustor. The heat is generated by an efficient, safe and technically proven process in the borehole where it is needed.

Our future challenge is to transform this technology into an industrial application. A field test in gas hydrate-bearing sediment is missing for this purpose. The ongoing development of the Schicks Combustor and the organization of a field test are comprehensive projects for which national and international project partners are from academics and industry are sought. It is also conceivable to transfer it to other areas of application for crude oil and natural gas production from conventional and other unconventional reservoirs.

What distinguishes the Schicks Combustor:

- The process is efficient: the heat is produced at depth where it is needed. Less than 15% of the methane produced is used to generate heat.

- The process is safe: the heat is generated in a closed system by a flameless catalytic combustion of methane in air. The reaction takes place below the ignition temperature of methane (595°C) and outside the explosion limits (4.4 vol.% to 17 vol.% in air). There is no contact between the reactor/reaction zone and the reactants and the environment. The exhaust gases are transported back to the surface.

- The process has been approved: Prototypes have been built and successfully tested on a laboratory and field scale. The laboratory reactor and the borehole tool are ready for operation and are available to companies for application tests.

Further special features:

- In future, it is planned that one reaction partner, ideally methane, will be obtained directly from the formation. The advantage is that the reaction is fed directly from the gas hydrate reservoir.

- Another advantage of the Schicks Combustor is that it can be used in combination with other processes such as depressurization or carbon dioxide injection.

- The Schicks Combustor can regulate the temperature of the gas flow in the production well and prevent the blockage of the pipes by newly formed hydrates.

The Schicks Combustor will be presented at the following events:

- AAPG Workshop: Gas Hydrates – From Potential Geohazard to Carbon-Efficient Fuel? 16-17 April 2019, Auckland , New Zealand

- Offshore Technology Conference: 6-9 May 2019, Houston, Texas, USA

Schicks, J., Spangenberg, E., Giese, R., Luzi-Helbing, M., Priegnitz, M., Beeskow-Strauch, B. (2013): A Counter-Current Heat-Exchange Reactor for the Thermal Stimulation of Hydrate-Bearing Sediments. - Energies, 6, 6, pp. 3002-3016. DOI: http://doi.org/10.3390/en6063002

Schicks, J., Spangenberg, E., Giese, R., Steinhauer, B., Klump, J., Luzi, M. (2011): New approaches for the production of hydrocarbons from hydrate bearing sediments. - Energies, 4, 1, pp. 151-172. DOI: http://doi.org/10.3390/en4010151